Automotive industry

Robotics

NEED HELP?CONTACT

US

PROJECT DETAILS

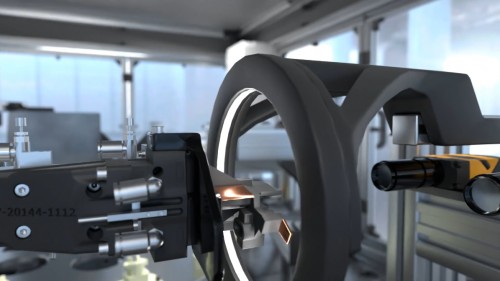

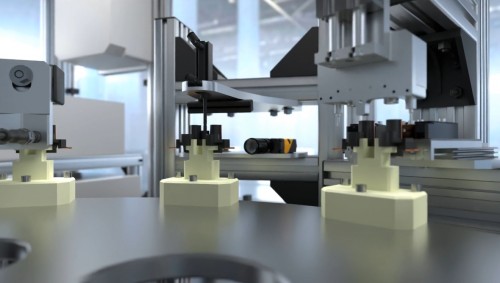

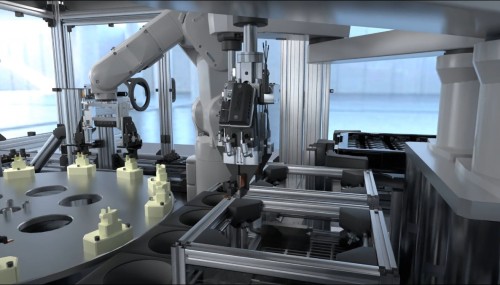

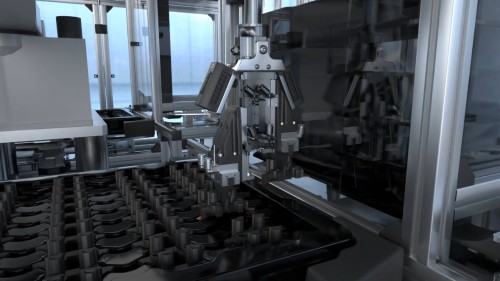

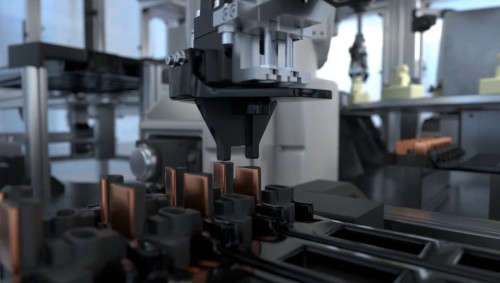

- Design, production of packing and testing cells.

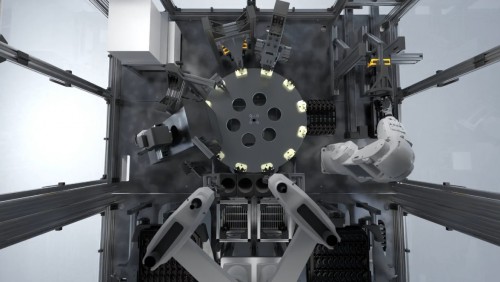

- Comprehensive line delivery including 3 units of Mitsubishi robots.

- Testing cell inputs are connectors, which are placed into nests by an operator. Afterwards, they are moved by an electrical drive to a robot´s collection position and placed into a nest on a turntable. Then connectors are tested (24V tester, VN tester), followed by camera inspection, connector core inspection, thread inspection, laser marking (QR code), QR code checking. The checked units are collected by SCARA robots from the turntable and moved to the packing cell. Every connector unit goes through an ionizer before they are loaded into palettes. The final line output means tested, marked, checked connectors loaded in stocked palettes.