Our company has been operating on the market for more than thirty years. During its operation, the company has implemented dozens of successful projects in the field of automation in Slovakia and abroad. Since its inception, the company has been focused on the design, assembly and complete supply of control and regulation systems for the automation of production lines, handling equipment and selected technological processes. Assembly and start-up of the lines is carried out in our assembly hall by our own workers. The company has implemented a certified quality management system according to ISO 9001, which confirms the quality of the work performed in all its areas and at the same time gives a guarantee of continuous improvement of processes and products for Procont's customers.

At PROCONT spol. s r.o. Prešov, certification according to ISO 9001:2015 (QMS) has been in place for a long time. At the end of 2024, the company successfully obtained certification under ISO 27001:2022 (ISMS) as well. The implementation process was challenging, which is why the documentation for QMS and ISMS was initially separated. The goal for 2025 is to merge both policies into one, eliminate redundant statements, and emphasize ESG principles. The new policy retains the version numbering from QMS and is therefore designated as version 1.2. The name „Quality Policy“ will be retained.

Company management is committed to implementing the following points

1. Quality (QMS): Ensuring the provision of flawless

products and services in accordance with the PDCA (Plan, Do, Check, Act)

approach. Our aim is to focus on meeting customer requirements and preventing

non-conformities.

2. Security (ISMS): Ensuring the protection of

company and customer information through asset management and regular review of

security measures.

3. Environment (E): Minimizing environmental

impacts, utilizing sustainable materials and technologies, and optimizing energy

and resource consumption.

4. Social (S): Promoting equality, diversity, and

inclusion, investing in employee training, and ensuring fair working conditions.

In return, we expect high-quality and professional work from our employees to

ensure customer satisfaction.

5. Governance (G): Fostering ethical and

transparent management, a leadership approach, and innovative thinking within

the organization. Managers must be leaders who guide and support their

subordinates, foster open communication, and motivate development.

6. Continuous Improvement:We are committed to

continuously improving processes, regularly evaluating performance, and

implementing measures to increase efficiency. We build effective and lasting

partnerships among employees, customers, and suppliers to achieve the highest

quality products and services.

7. Active Customer Acquisition: Our company

supports the ethical and transparent development of business opportunities among

all employees. We will support every good idea or activity that could lead to

acquiring a new customer or contract.

OUR STORY

Since the beginning of our activity, we have focused on the implementation of electrical projects, PLC programming, designs and supplies of control and visualization software.

Since 2001, the company's activities have expanded to include the supply of automated handling solutions, when the department of machine construction began to operate in the company. We gradually designed and perfected a comprehensive range of handling equipment and various conveyors. Later, we started using other handling subgroups, which we supplemented with our grippers and other transport devices for the complex implementation of automated lines.

Gradually, the company began to deal with engineering and supply activities in the field of supplying larger investment and technological units.

In 2010, the operation and focus of the company was supplemented by the supply of robots, robotic workplaces and complex lines for various areas of industry.

Since 2019, we have become a successful holder of the ISO 9001:2015 certificate.

Our next vision for the 21st century is to offer products and solutions designed and compatible for Industry 4.0.

RANGE OF SUPPLIES

ENGINEERING AND SUPPLYING ACTIVITIES

- Control systems,

- Visualization of technological processes,

- Measurement and management of technological processes,

- Speed regulation of DC and AC drives,

- Electrical distribution and switchboards,

- Project activity,

- Application software development,

- Inspection, checking and professional examination of electrical equipment.

PRODUCTION AND DELIVERY OF ROBOTIC WORKPLACES AND AUTOMATED HANDLING SOLUTIONS

- Robotized lines,

- Manipulators,

- Manual handling devices,

- Single-purpose equipments,

- Technological equipments of warehouses,

- Conveyors,

- Transport carts,

- Application software development.

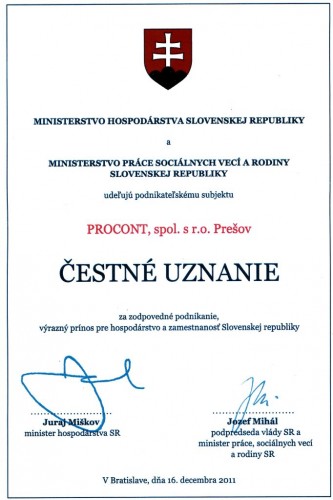

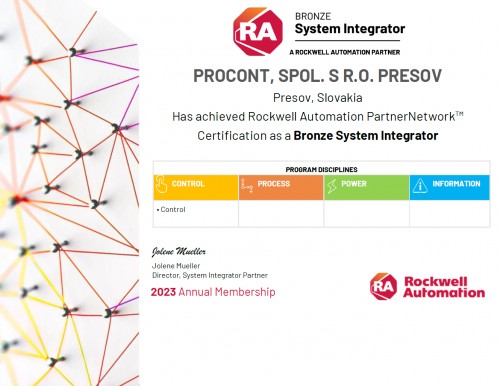

CERTIFICATES

OUR PROJECTS IN THE WORLD