Thanks to constant evolution, robotics has acquired competence in the key areas of sensing, cognition and control. It thus brings ever higher reliability, accuracy, productivity, quality and many other significant and important features to the industry. In the field of robotics, our company focuses on the design of robotic workplaces, which we will custom design for you according to the technical specifications you enter.

INDUSTRIAL ROBOTS

They represent universal automated devices performing movements similar to the movements of a human hand or arm. We cooperate with leading robot manufactures (Mitsubishi Electric, ABB, Kuka, Fanuc), whose products are implemented to our robotic workplaces with the support of modern simulation tools.

INTO OUR WORKPLACES WE INTEGRATE

SPHERICAL 6-AXIS ROBOTS

- Developed especially for performing difficult operations with the need for high accuracy, speed, reliability and precision,

- Large arm reach and compactness,

- Equipped with the FA-IT function, which simplifies the integration into the industrial automation of the enterprise and the integration of Industry 4.0,

- Pick & Place applications, operation of machines (CNC machining centres, injection moulding machines), assembly of complex parts, handling of large loads, palletizing, screwing…

SCARA ROBOTS

- Developed especially for high-speed manipulation in the horizontal direction,

- Equipped with the FA-IT function, which simplifies the integration into the industrial automation of the enterprise and the integration of Industry 4.0,

- Handling of small loads, pick & place application, packaging, filling, assembly, sorting, marking of products, microoperations)…

COLLABORATIVE ROBOTS (COBOT)

- Flexible and easy-to-program robots working safely in direct cooperation with a human

- Simple positioning using buttons without any need to use a teaching box for programming

- Pick & Place applications, assembly, CNC and device operation, quality control, handling, packaging…

SINGLE-PURPOSE EQUIPMENT

Streamlining the production processes of our lines inspired us to create and design equipment that comes from our own workshop. An example of such a device is the Rotary hopper or Hopper, which offers a precisely adapted supply and correct orientation of the fed components. They can thus replace classic vibrating containers.

ROTARY HOPPER

By rotating the drum, the delivered parts are caught by means of internal paddles. Subsequently, they reach the dosing bar connected to the vibration drive and gradually vibrate through the elements designed for their adequate positioning. Correctly oriented parts are then guided directly to the designated collection point.

HOPPER

By rotating the rotary table, the fed components are moved to the robot's picking zone. This is captured by a camera that evaluates and sends the coordinates of the recognized part directly to the respective robot. The incorrectly oriented component is then turned using a gripper.

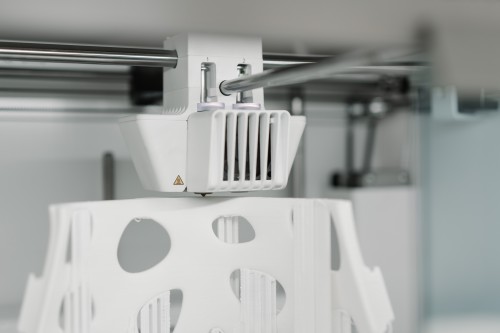

3D PRINTING

We are equipped with 3D printers with LPD (Layer Plastic Deposition) technology, which allow us to print form-demanding or prototype parts intended for functional tests in our workplaces. They also offer a wide portfolio of materials for various applications.

PROCESSES PERFORMED BY OUR WORKPLACES

HANDLING

STACKING

PALLETIZATION

GLUEING

SCREWING

PRESSING

CONTROL

PACKAGING

ASSEMBLY

TESTING

LASER MARKING

CUTTING

AND OTHER…