Čo ponúkame v oblasti priemyselnej automatizácie

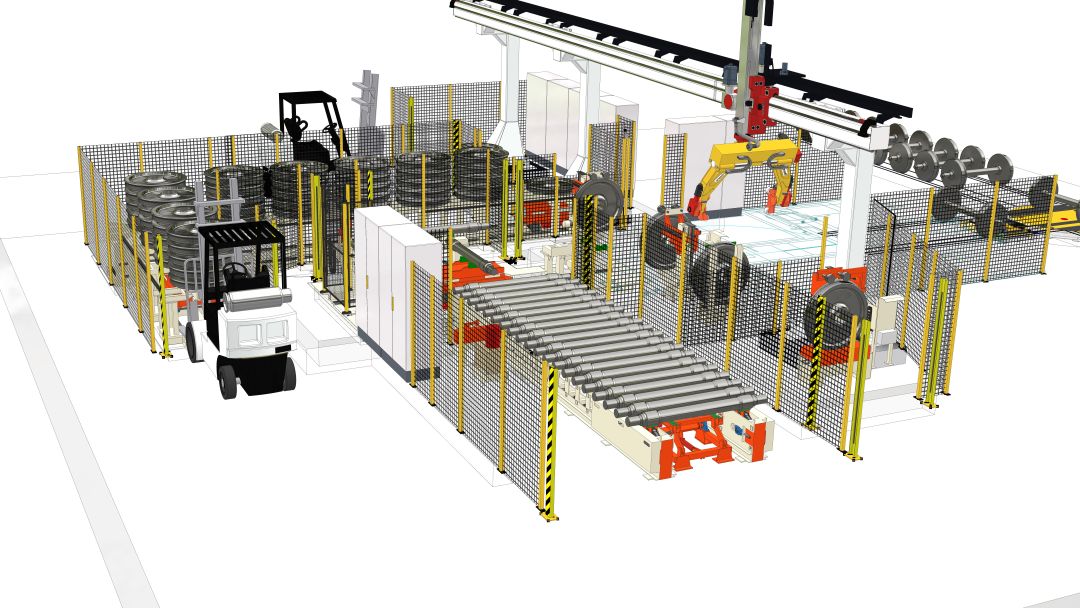

Ponúkame vám viac ako 30 ročné skúsenosti v oblasti priemyselnej automatizácie so zameraním na projekčnú, výrobnú a dodávateľskú činnosť v oblasti riadenia technologických procesov, manipulačných liniek a techniky a robotizovaných pracovísk.

O nás

Sme na trhu automatizácie od roku 1991. Máme za sebou úspešné projekty v rôznych priemyselných odvetviach na Slovensku aj v zahraničí a množstvo spokojných zákazníkov. Disponujeme kvalitným, zanieteným a profesionálnym tímom pracovníkov.

Spoznajte násRokov skúseností

Kvalifikovaných pracovníkov

Úspešných projektov

Zákazníkov a partnerov

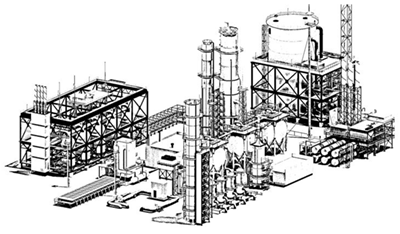

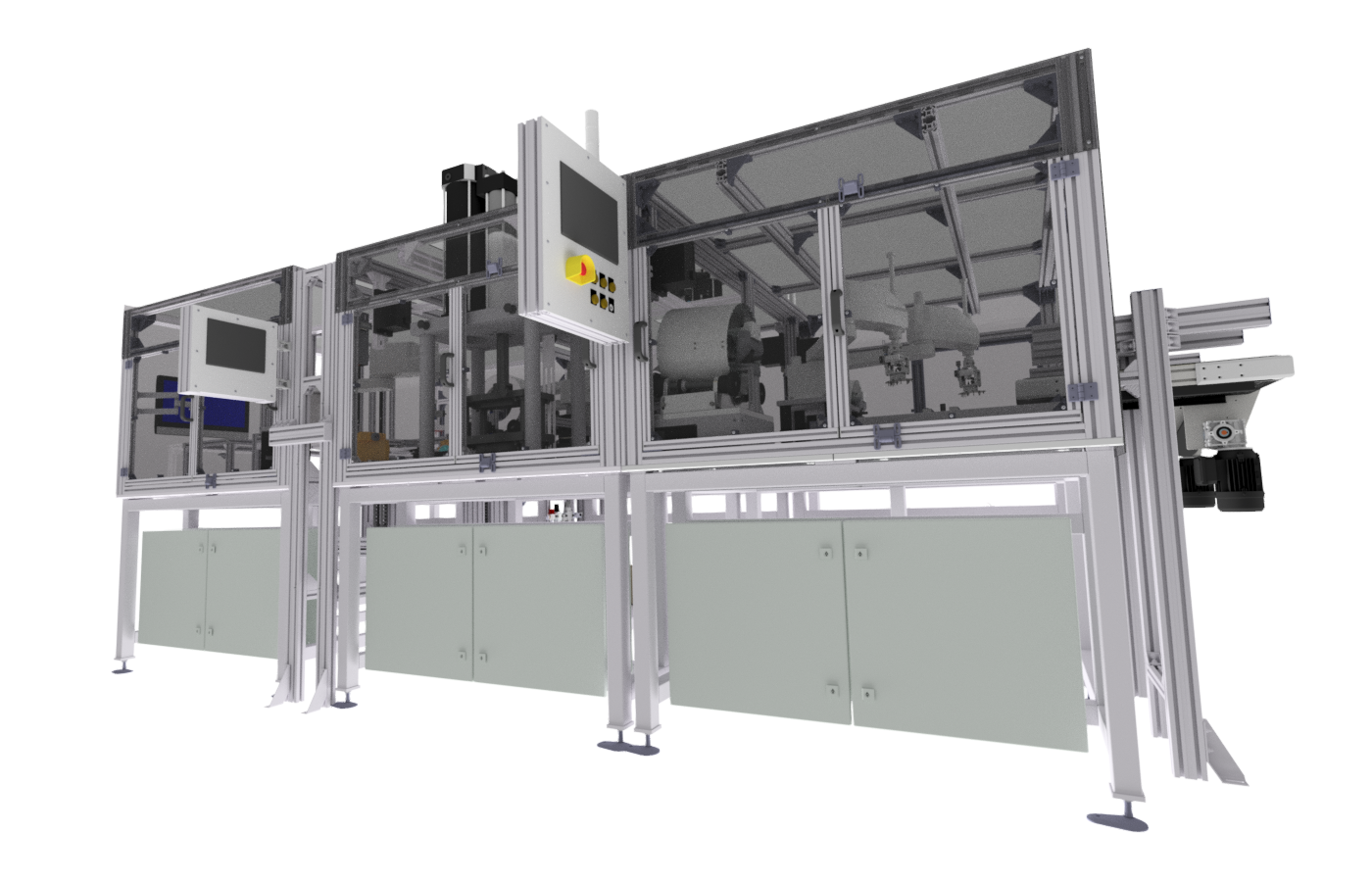

Priemyselná automatizácia

Je súčasťou tretej priemyselnej revolúcie, ktorá spočíva v mechanizácii mnohých procesov a vzniku nového odvetvia nazývaného „Priemysel 4.0“. Zavádza používanie moderných výrobných procesov, v ktorých človek len kontroluje automatmi vykonávané operácie.

Kontaktujte násPrečo automatizovať?

Konkurencieschopnosť

Znižovanie nákladov, skracovanie výrobných lehôt a zjednodušovanie procesov prinášajú podnikom lepšiu pozíciu na trhu a vyššiu konkurencieschopnosť.

Produktivita

Jednotvárne a ťažké operácie sú vykonávané pomocou priemyselnej automatizácie vďaka čomu môžu ľudia venovať svoj čas kvalifikovanejším a náročnejším úlohám.

Bezpečnosť

Implementácia bezpečnostných systémov, odbremeňovanie operátov od namáhavých úkonov či práce v škodlivom alebo nebezpečnom prostredí zvyšuje ich ochranu zdravia.

Kvalita

Automatizačné prostriedky sú schopné dosahovať presnosť a rýchlosť presahujúcu ľudské schopnosti. Zároveň ponúkajú jednoduchú kontrolu, monitoring prebiehajúcich procesov a eliminujú chybovosť ľudského faktora.

Výber z našich najnovších projektov